Our facilities include 3D printers for Fused Filament Fabrication (FFF) printing of commodity and high-performance thermoplastic polymers, for both mono- and multi-material parts,

and photopolymerization-based SLA and DLP printers for commercial and custom resins and oils.

We also developed a custom printer for the 3D printing of high viscosity photocurable resins and liquid elastomeric compounds.

Fused Filament Fabrication (FFF)

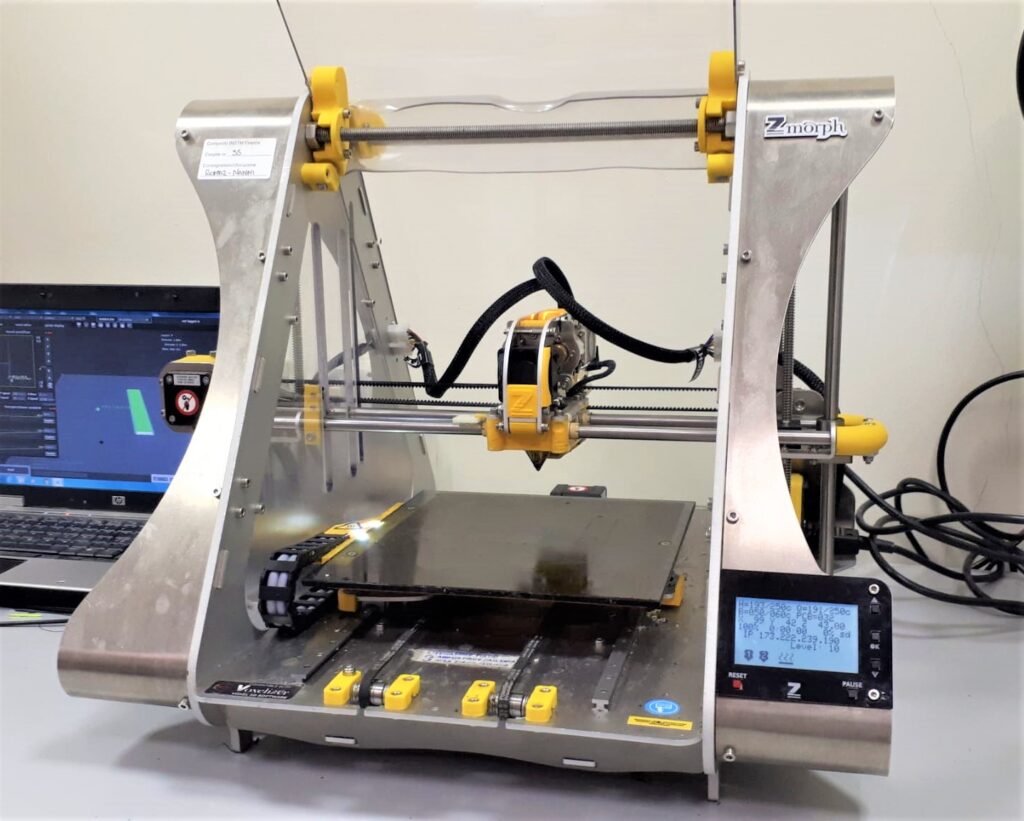

ZMorph

Multiple head double extruder 3D printer. Allows for the simultaneous printing with two different filaments for multimaterial parts.

| Model: | ZMorph 2.0 S |

| Specifications: | Filament diameter: 1.75 mm Print volume: 250 x 235 x 165 mm Min layer thickness: 0.1 mm Machine resolution xy: 0.025 mm; z: 0.05 mm Max nozzle temperature 255°C, max galss bed temperature 100°C. Multiple heads: single nozzle extruder, dual nozzle extruder, mixing nozzle extruder, laser marking. Nozzle size range : 0.2- 0.8 mm Non-proprietary slicer software |

Apium P155

FFF printer suitable for high performance polymers (i.e. PEEK, PEI)

| Model: | Apium P155 |

| Specifications: | Filament diameter: 1.75 mm Print volume 140 x 135 x 148 mm Max nozzle temperature: 540° C, max glass bed temperature: 160° C. Nozzle size range: 0.2- 0.8 mm Min. layer thickness: 0.1 mm Machine resolution xy: 0.0125 mm; z: 0.05 mm Closed printing chamber with additional upper heater Slicing software: Simplify 3D |

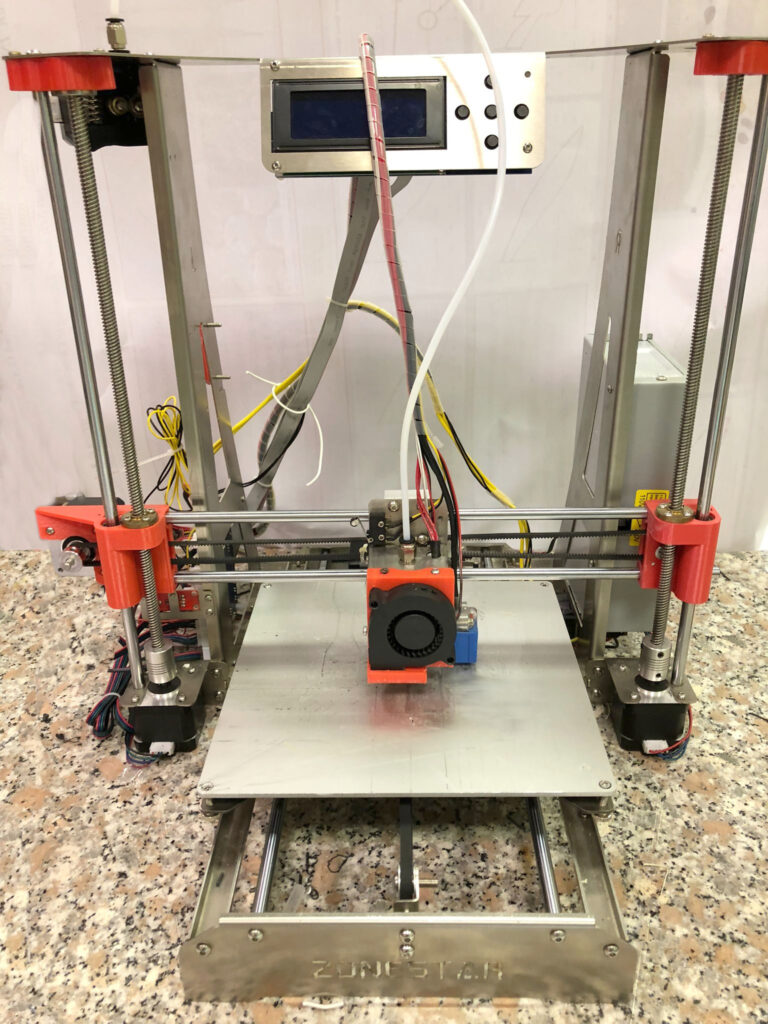

ZoneStar

Single extruder FFF 3D printer for polymers

| Model: | ZoneStar P 802 |

| Specifications: | Filament diameter: 1.75 mm Print volume: 220 x 220 x 240 mm Max nozzle temperature: 255° C, max metal bed temperature: 100° C. Nozzle size: 0.4 mm Min. layer thickness: 0.1 mm Machine resolution xy: 0.012 mm; z: 0.05 mm Non-proprietary slicer software |

Photopolymerization-based printing

Formlabs SLA

Stereolithography (SLA) 3D printer based on laser photopolymerization, suitable for commercial acrylic resins.

| Model: | Formlabs Form 2 |

| Specifications: | Print volume: 145 × 145 × 175 mm Layer thickness: 25, 50, 100 µm Laser spot: 140 µm Laser: UV (405 nm), 250 mW power Software: Formlabs PreForm |

Elegoo DLP

Digital Light Processing (DLP) 3D printer based on UV projection, suitable for custom developed resins and oils.

| Model: | Elegoo Mars 2 pro |

| Specifications: | Print volume: 129 x 80 x 160 mm Layer thickness: 10 – 200 µm XY Resolution: 50 µm Projector: UV (405 nm) Software: ChituBox |

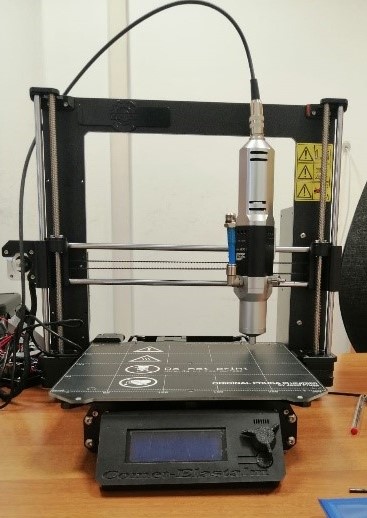

Prusa – Viscotec custom

Custom 3D printer based on an FFF printer modified with an screw pump head capable of handling high viscosity fluids, suitable for the 3D printing of photocurable pastes and fluids. The system feeds pressurized material through a nozzle and, after the deposition of each layer, performs the polymerization via a UV-lamp.

See Project Elastalm.

| 3D printer: | Prusa i3 MK3S+ |

| Extruder head: | Viscotec Vipro-HEAD 3 |

| Specifications: | Print volume: 250 × 210 x 210 mm Layer thickness: 100 – 300 µm Nozzle diameter: Viscosity range: 5 – 300 mPas Polymerization lamp: UV (405 nm) Software: Simplify3D |