We are proud to announce our latest publication in the Journal of Applied Polymer Science (Wiley), “Toward sustainable rubber compounds: the use of waste raw materials”!

The sustainability and circular economy in the plastic and rubber industry are important targets to fight climate change.

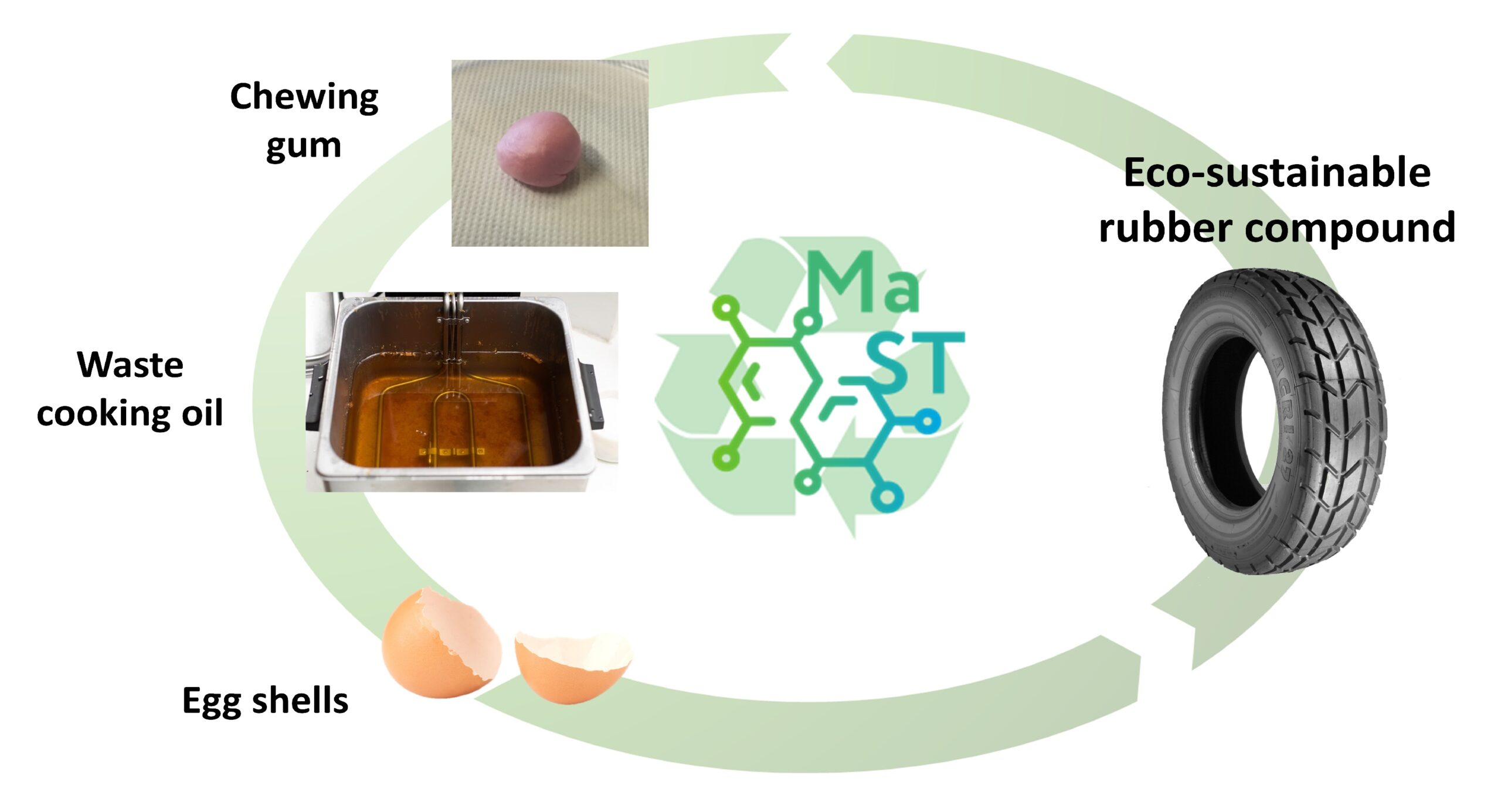

Our work originates from the idea of realizing sustainable rubber compounds made in large part of secondary raw materials. meaning materials coming from waste sources.

In collaboration with Dr. José Augusto Berrocal (from Adolphe Merkle Institute), we researched the use of waste chewing gums (which pollute our cities), egg shells and waste cooking oil from food frying to manufacture sustainable rubber compounds with negligible loss of performances compared to traditional rubber.

Check out our work here!

Italiano

La sostenibilità e economia circolare nell’industria della plastica e della gomma sono obiettivi di cruciale importanza per combattere il cambiamento climatico.

La nostra ricerca parte dall’idea di realizzare mescole elastomeriche (gomme) sostenibili composte per la maggior parte da materie prime seconde, ovvero materiali da fonti di scarto.

Il nostro lavoro ha investigato l’utilizzo di gomme da masticare, gusci d’uovo e olio di scarto da frittura per realizzare mescole elastomeriche ecosostenibili con minima riduzione di performance rispetto a gomme tradizionali.

Abstract

https://onlinelibrary.wiley.com/doi/10.1002/app.53750

This article aims to realize a sustainable rubber compound made in large percentage of secondary raw materials. Waste chewing gum (WCG) has been studied as source of rubber and added in 25% by weight in an ethylene propylene diene monomer based compound in view of a circular economy and eco-friendly rubber manufacturing. Biobased CaCO3 extracted from waste eggshells was used as extender agent and waste cooking oil from potato chips frying was employed as processing aid. The rubber extracted from WCG resulted to be polyisobutylene (PIB) whereas the main component of the WCG is polyvinyl acetate (PVAc). The addition of the WCG modifies the rheological properties of the rubber compound leading to a better filler–filler and filler–matrix interaction. On the other hand, the presence of both PVAc and PIB leads to lower mechanical properties (max torque 6 vs 10 dNm in curing test) but also higher elongation at break (600% vs 500%). The WCG also increases the selfadhesion of the rubber and decreases the glass transition temperature allowing for the use of these compounds at lower temperatures thanks to its good tack behavior.